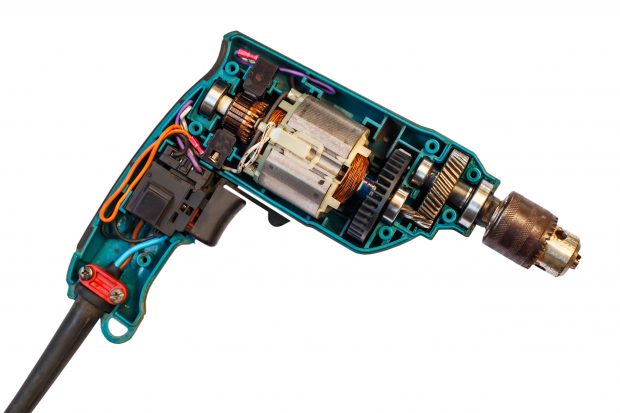

Fixing power tools could be difficult for most people. After all, power tools are complicated pieces of equipment. In most cases, the best approach is to first try to understand how these handheld tools work. Moreover, try to learn more about each component found inside. When people become familiar with these tools, they start to learn the uses and importance of each part.

Among the different power tools, the carbon brush is one of the most essential parts. This electric circuit component is also referred to as a motor brush. Its primary function is to make an electric motor work efficiently. Hence, with a damaged carbon brush comes a malfunctioning power tool. Those who understand the crucial role of this component know that repairing or replacing a carbon crush is more likely to make a power tool function efficiently again.

If you want to know more about carbon brushes, here’s an article that you might want to read:

Troubleshooting And Maintenance Tips For An Electric Power Tool

Before you jump into the benefits that carbon brushes offer, you may want to know some troubleshooting and maintenance tips for power tools. These little hacks can help you save time, money, and effort in the long run.

- Calibrate The Power Tool Regularly

Calibration keeps the power tool in good running condition. After all, calibration enables the proper alignment of each vital part. For best results, a tool owner may follow a tool maintenance checklist to know the most effective way to calibrate their tools.

- Replace Carbon Brushes

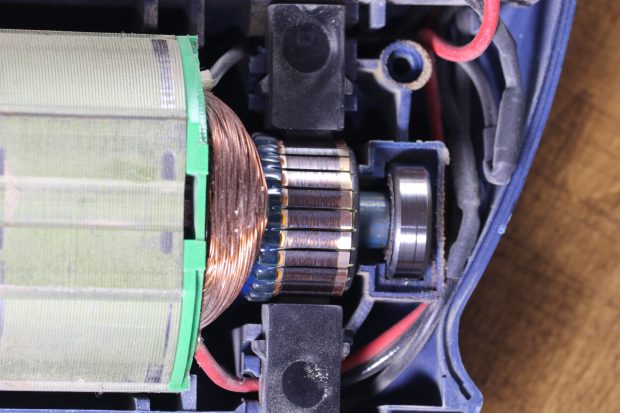

In most cases, a carbon brush replacement is inevitable. Some power tool stores can help you further understand carbon brushes and their uses. For instance, Top Deals Online explains that the carbon brush is a tiny part of an electric motor that conducts the electrical current between two areas of a motor or generator: the stationary and rotating wires. Due to their essential function, neglecting your carbon brushes is a common cause of power tools breaking prematurely.

- Clean Thoroughly

Like any other machine or tool, you should clean power tools thoroughly. For this purpose, workers may use compressed air to remove the dirt on the tools. To optimize the cleaning process, tool owners may need to lubricate the power tools often. In addition, the tools should have a clean, secure toolbox for storage. If you’re just beginning to use power tools, you may start using the most used and keep the complex types in the meantime.

Benefits Of Carbon Brushes

1.Self-Lubrication

The self-lubricating feature of carbon brushes makes them better than their counterparts. With this property, carbon brushes help tools be more efficient and consistent. Moreover, it can function nonstop since there’s no need for manual lubrication. However, users do need to check regularly if the carbon brushes are still able to self-lubricate. Failed lubrication may wear and tear the motor faster than usual.

2.High Melting Point

Generally, carbon brushes have a melting point of around 3,500°C. Compared to other types of brushes, carbon brushes have a higher melting point. This way, it can withstand extreme heat as it takes longer to dissolve. Hence, workers could use the tools even in super-hot situations. Of course, users should still stay mindful of this because they may use it in temperatures beyond its limit.

3.Temperature Resistance

Carbon brushes are known to have a temperature opposite to their motor. In simpler terms, the higher the motor’s temperature is, the lower the carbon brush is. This way, power tools using it could work continuously and consistently for a generally longer time than other types of brushes.

4.Soft Material

Carbon brushes generally have a soft texture due to the materials used. This characteristic gives the brushes a consistent contact point. Moreover, it efficiently minimizes the friction between two contact points. The soft material of carbon brushes can also counter an electric flow, making them less damaging. Together, the soft quality and better friction management prevent these parts from damaging the commutator.

5.Replaceability

In most cases, carbon brushes are one of the most worn components of hammer drills and other tools. The more a tool is used, the more damages carbon brushes receive. While there are ways to slow down the wear and tear of carbon brushes, they’ll still incur significant damage over time. Fortunately, carbon brushes are widely available in hardware stores, making it easy to find replacements.

6.Necessity For Torque

Because the carbon brushes are stator-fixed, they can join the plates on the rotator. As the latter functions, the current is supplied efficiently with the help of high-quality carbon brushes. This way, carbon brushed become essential to torque as well as to electric power tools.

7.Commutator-Friendly

The qualities of a good carbon brush make it an ideal part of any electric power tool. Specifically, carbon brushes enable excellent commutation. The soft elements of carbon also make it a perfect component because it could fit easily into the shape of the commutator.

8.Cost-Effectiveness

In choosing between carbon brush replacement and power tool replacement, the former is more affordable. Although carbon brushes need compatible replacement, they still cost less. Moreover, its capacity for self-lubrication and low maintenance makes it even less expensive.

9.Excellent Conduction

Because it’s carbon-based, it has high conduction properties. Because of this, it works perfectly in connecting the electric current from the static to the non-static components of the motor. Furthermore, good conduction ensures proper electrical transmission so that the tools can work properly.

Wrapping Up

Power tools are essential in cutting, grinding, and drilling. Yet, once damaged, they can be challenging to replace. Luckily, there are maintenance and troubleshooting tips and tricks that can help power tool owners. Through these tips, you can extend the lifespan of your tools. Even better, these tips and tricks could retain or even improve the performance of your power tools.

One way of maintaining a power tool is to have an excellent carbon brush replacement. This article has discussed the different benefits that carbon brushes provide to power tools. These include self-lubrication, high melting points, and temperature resistance.

In addition, carbon brushes are generally soft and replaceable. They’re also excellent conductors, making them a better fit than copper brushes and other counterparts. With these benefits, you should seriously consider choosing a carbon brush.